zoom_in

zoom_in

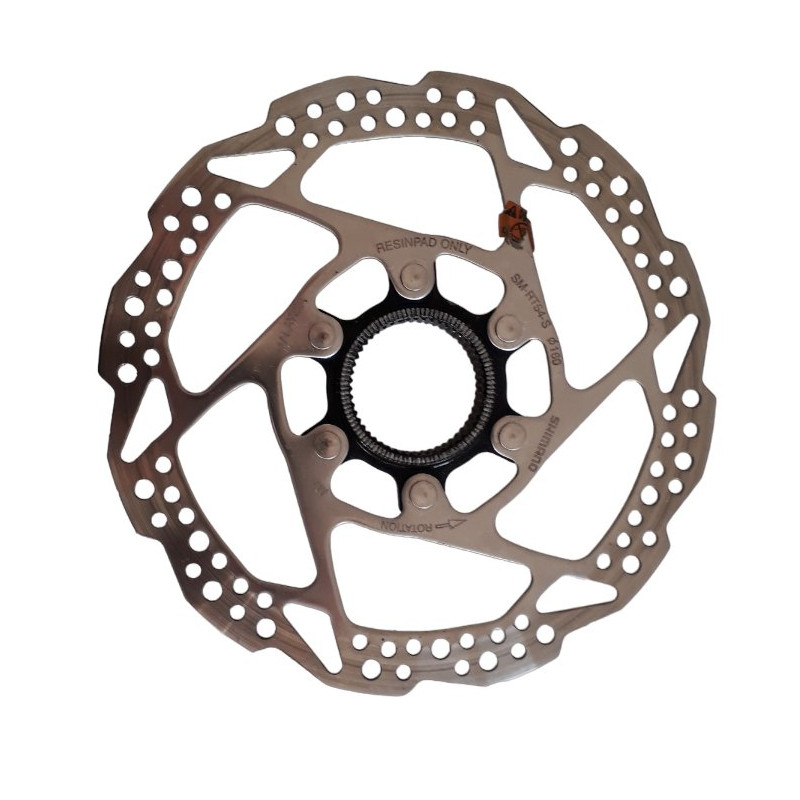

Shimano SM-RT54-S disc brake center lock 160 mm

- SM-RT54-S

- 1 Item

- Used

€4.99 VAT included

Everything you need to know about Centerlock brake rotors

Brake rotors are a crucial component of any braking system, whether it is a car, motorcycle, bicycle or other form of transportation. Among the various types of brake rotors available on the market, Centerlock brake rotors have quickly established themselves as a popular option, offering significant advantages in performance and convenience. In this article, we will explore in depth what a Centerlock brake rotor is, how it works, what its benefits are, and how to maintain it.

What is a Centerlock brake disc?

A Centerlock brake disc is a special type of brake disc used mainly in the automotive industry, but also increasingly commonly in the field of cycling. The main feature that distinguishes a Centerlock brake disc from other types of discs is its mounting system.

Unlike traditional brake rotors, which are typically attached to the wheel using six or more bolts, Centerlock brake rotors are attached to the wheel hub using a single center nut. This center nut is specially designed to hold the brake rotor securely in place, eliminating the need for multiple mounting bolts. This simplified fixing system has many advantages, as we will see later.

How does a Centerlock brake disc work?

The operation of a Centerlock brake rotor is similar to traditional brake rotors. When you step on the brake pedal, the brake fluid is compressed, which pushes the brake pads against the rotor. The friction between the pads and the disc slows the rotation of the wheel, causing the vehicle to stop.

The main difference is how the brake disc is attached to the wheel. In the case of a Centerlock brake disc, the center nut holds the brake disc in place very securely. This means that the brake disc remains perfectly centered in relation to the wheel hub, improving stability and braking precision.

Advantages of Centerlock brake discs

Centerlock brake rotors offer several advantages over traditional brake rotors, which explains their growing popularity. Here are some of the most notable benefits:

Ease of installation:

The Centerlock mounting system is simpler and quicker to install than multiple bolt systems. This reduces the time required for maintenance and repairs.

Improved stability:

The Centerlock design ensures that the brake disc remains perfectly centered, eliminating vibration and providing more stable braking, even at high speeds.

Reduced maintenance:

Due to their robust design, Centerlock brake rotors require less maintenance than traditional rotors. They are less prone to uneven wear.

Versatile Compatibility:

Centerlock brake rotors are becoming increasingly available for a variety of vehicles, including cars, motorcycles and bicycles. This makes them versatile and accessible to a wide range of users.

Improved aesthetics:

Some users like the cleaner, more modern look of Centerlock brake rotors compared to bolt-on systems.

Maintenance of Centerlock brake rotors

Although Centerlock brake rotors require less maintenance than traditional rotors, maintaining them properly is essential to ensure their durability and efficiency. Here are some tips for maintaining Centerlock brake rotors:

Regular cleaning:

After muddy or dusty rides, clean the brake rotors thoroughly using brake cleaner and a clean cloth. Be careful not to spray cleaner on the brake pads.

Visual inspection:

Check the condition of the brake rotors regularly for excessive wear or signs of deformation. If you notice any problems, replace the drives as soon as possible.

Changing the pads:

Brake pads should also be monitored and replaced when they reach their wear limit. This guarantees optimal braking.

Tightening the Centerlock Nut:

Make sure the Centerlock nut is properly tightened following the manufacturer's specifications. An improperly tightened nut can cause braking problems.

Call a professional:

If you are unsure about maintaining your Centerlock brake rotors, it is recommended that you have a qualified mechanic or technician perform the necessary maintenance and repairs.

In conclusion, Centerlock brake discs are an important innovation in the field of braking systems. Their simplified design, improved stability and versatility make them an attractive choice for many vehicle types. By ensuring regular maintenance, you can ensure that your Centerlock brake rotors perform optimally for years to come. Investing in quality brake rotors is essential for your safety on the road, whatever form of transport you use.

Remember, to achieve the best results with Centerlock brake rotors, it is essential to follow the manufacturer's recommendations and seek qualified professionals when necessary. With proper maintenance, you will be able to take full advantage of the benefits of this advanced braking technology.